Clean Technology

Lignin-Metal Complex Formation to Enhance Biofuel Production Processes

WARF: P100184US02

Inventors: JunYong Zhu, Hao Liu

The Wisconsin Alumni Research Foundation (WARF) is seeking commercial partners interested in developing a method to enhance enzymatic hydrolysis of biomass material.

Overview

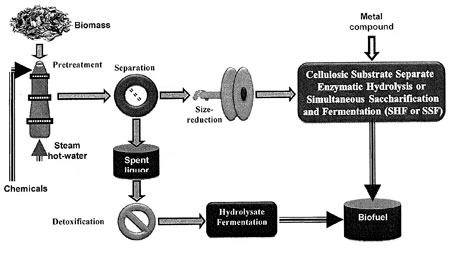

Lignocellulosic biomass is a plant biomass that is made up of cellulose, hemicelluloses and lignin, and is an ideal raw material for use in biofuel production. The premier lignocellulosic biomass crop used for energy purposes is sugarcane. Researchers have speculated that conversion of lignocellulose material could yield 25 to 50 billion gallons of ethanol per year if the fermentation process for lignocelluloses can be optimized. Enzyme accessibility of the starting material is a key limiting factor in hydrolysis of lignocellulose. A pretreatment step may be required to make the material suitable for cellulolytic hydrolysis, which converts the cellulose into fermentable sugars.

Previous research has uncovered that lignin is one of the key non-productive enzyme adsorption compounds present in lignocellulosic biomass. Lignin needs to be removed or reduced through a pre-washing and separation step. The washing steps typically involve high volumes of water at high temperatures to isolate the cellulose for enzymatic saccharification (breaking down of the complex carbohydrates). The significant water and energy consumption results in high costs and serious environmental concerns.

Other techniques to reduce the effects of lignin include the use of exogenous protein to mask lignin and the use of surfactants to block lignin and improve enzymatic hydrolysis. However, proteins are too expensive to use in commercial, large-scale production. Surfactants may cause foaming that negatively impacts saccharification and fermentation, and can be expensive to implement effectively. A method to inhibit enzyme adsorption by lignin during biofuel production is needed.

Previous research has uncovered that lignin is one of the key non-productive enzyme adsorption compounds present in lignocellulosic biomass. Lignin needs to be removed or reduced through a pre-washing and separation step. The washing steps typically involve high volumes of water at high temperatures to isolate the cellulose for enzymatic saccharification (breaking down of the complex carbohydrates). The significant water and energy consumption results in high costs and serious environmental concerns.

Other techniques to reduce the effects of lignin include the use of exogenous protein to mask lignin and the use of surfactants to block lignin and improve enzymatic hydrolysis. However, proteins are too expensive to use in commercial, large-scale production. Surfactants may cause foaming that negatively impacts saccharification and fermentation, and can be expensive to implement effectively. A method to inhibit enzyme adsorption by lignin during biofuel production is needed.

The Invention

UW-Madison researchers have developed a method of cellulose hydrolysis using metal compounds to prevent the non-productive adsorption of enzymes by lignin during biofuel production. Metal compounds such as ferrous, magnesium and calcium compounds are used to form lignin-metal complexes. The formation of the lignin-metal complex prevents adsorption of enzymes by deactivating the non-productive adsorption sites on lignin. As a result, more enzymes are available for efficient cellulose saccharification. The formation of a lignin-metal complex allows a pretreatment step with no high-volume wash involved, reducing the energy and water costs associated with the biofuel production process.

Applications

- Sugar production through biomass utilization and similar enzyme and lignocellulose systems

- Biofuel production

Key Benefits

- Requires fewer lignin removal steps, resulting in significantly improved biofuel production efficiency

- Allows simultaneous saccharification and cofermentation of the lignocellulose solid substrate and the hemicellulose sugar stream

- Reduces or eliminates need to wash the cellulose fraction before enzymatic saccharification, which significantly reduces fresh water usage in commercial applications

Additional Information

For current licensing status, please contact Mark Staudt at [javascript protected email address] or 608-960-9845

Figures